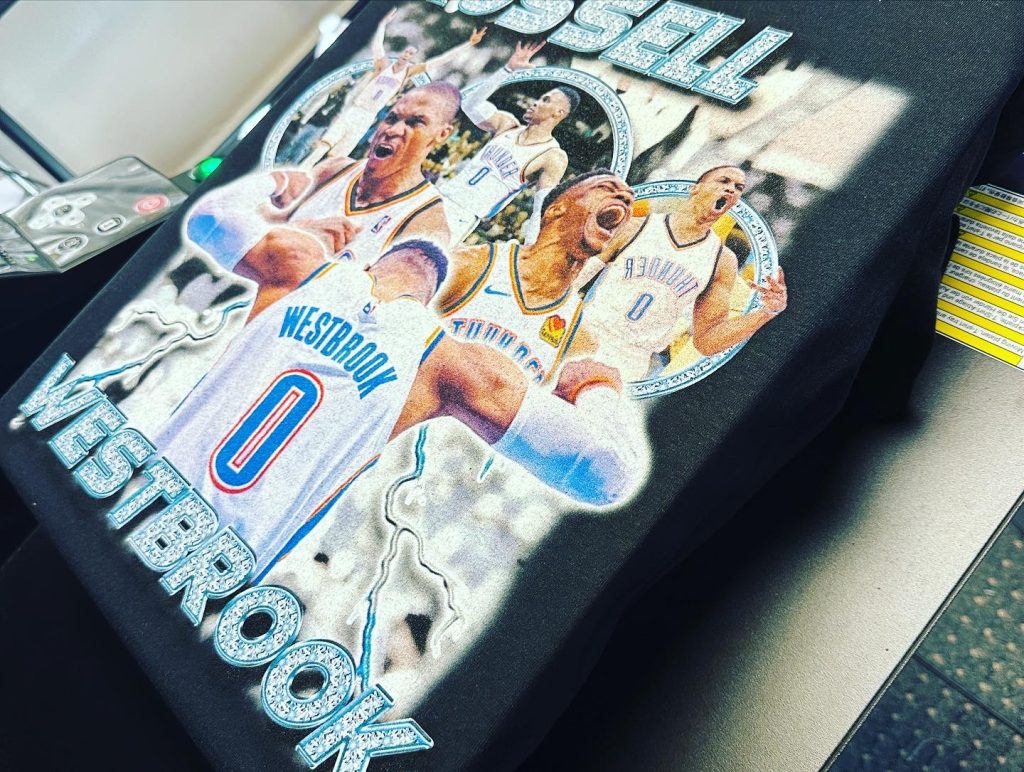

CUSTOM DIRECT-TO-GARMENT PRINTING SERVICES

NAMPA'S BEST DIGITAL T-SHIRT PRINTING SERVICE

Get shirts made fast at The Print Plug in Nampa, one of the best DTG shops around! Our direct-to-garment printing service includes full color custom graphics and one-day turnaround. Need them sooner? Last minute t shirt printing is kind of our thing... Just give us a call at (986)777-9466. Our DTG team will do what we can to make sure you don't miss your deadline! The Print Plug is Nampa, Idaho's only answer to the frequently-used search term 'same day direct to garment printing near me'.

5-STAR GOOGLE RATING

Elevate your style and creativity with The Print Plug's unrivaled custom Direct-to-Garment printing service right here in Nampa, Idaho. DTG printing unleashes a spectrum of vivid colors and intricate designs, and the best part is, there are no minimum order restrictions. And, thanks to the efficiency of our custom t-shirt printing setup, we are able to offer turnarounds as fast as SAME-DAY! Whether you're planning a special gift, showcasing cherished photographs on a t-shirt, coordinating outfits for unforgettable bachelor and bachelorette parties, reuniting with customized apparel, or simply looking for small-run custom t-shirt shirt orders, The Print Plug has got your back (literally!) with our direct-to-garment printing service, including no minimum custom printed t-shirts and more

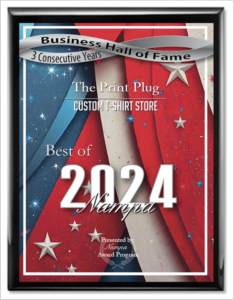

Our commitment to excellence extends beyond the creative process. With a sterling 5-star Google rating and the distinguished title of Best Custom T-Shirt Shop in Nampa for two consecutive years, we pride ourselves on delivering exceptional results. Plus, we understand the importance of time, which is why we offer next-day turnaround on most direct-to-garment custom clothes orders, ensuring your custom clothing is ready when you need it.

At The Print Plug, we believe in making your wardrobe uniquely yours. Our custom DTG printing service allows you to express your individuality with unmatched color vibrancy and design intricacy. So, whether it's for a special occasion, a memorable gift, or to stand out from the crowd, we invite you to explore the limitless possibilities of DTG printing with The Print Plug in Nampa. Call us today at 986-777-9466, and let's turn your ideas into wearable masterpieces.

Or use our online quote request form.

When time is of the essence, we've got your back! The Print Plug offers a 24 hour turnaround or sooner on most DTG custom clothes orders. With full-color prints, no minimum orders, and our money-back guarantee, you can rest easy knowing that you won't be sacrificing quality.

2022 & 2023 WINNER OF 'BEST CUSTOM T-SHIRT SHOP'

DTG shirt printing made easy! Need a photo printed on a shirt? We got you. Need some company outfits for a last minute meeting? No problem. Need a last minute gift idea? We've got you covered with our last minute t shirt printing services.

Get your custom dtg printing done fast at The Print Plug in Nampa. We are Idaho's go-to source for quick custom t shirt printing and more. We offer 24 hour turnaround. Need your shirts same day? Give us a call and we'll do everything we can to help you make your custom t-shirt printing deadline!

We proudly offer the following services:

- Screen Printing

- Embroidery

- Direct-to-Garment Printing

- Heat-Transfer-Vinyl

- Direct-to-Film Printing

- Stickers & Decals

- Banners & More

WINNER OF BEST CUSTOM T-SHIRT SHOP 3 YEARS STRONG

We are so proud and excited to be recipients of Nampa's Best Custom T-Shirt Shop Award for two years running! We are grateful to all of our customers who have supported us in this journey, and look forward to serving you in your custom clothes and apparel printing and embroidery needs for many more years to come. Read the full press release here!

24 HOUR TURNAROUND ON MOST CUSTOM T-SHIRT ORDERS

- Shirts

- Pants

- Hoodies / Sweaters

- Canvas Bags

- Mouse Pads

- Koozies

- Coasters

- Plus More

Call The Print Plug today to find out how we can help breathe life into your custom shirt project with no minimums and 24 hour turnaround! With a friendly and knowledgeable staff, you can rest easy knowing your custom Direct-to-Garment printing job is in good hands. From the design process to the finished product, your satisfaction is guaranteed.

NO MINIMUM ORDERS!

ONLY NEED 1 SHIRT PRINTED? NO PROBLEM (PRICE BREAKS ON LARGER ORDERS)

WHY CHOOSE CUSTOM DTG T SHIRT & APPAREL PRINTING

SATISFACTION GUARANTEED!

LOVE IT OR RETURN IT. NO QUESTIONS ASKED.

NO SET-UP FEES!

SAVE MONEY WITH NO ARTWORK OR SCREEN FEES TO WORRY ABOUT!

STOP BY OUR NAMPA LOCATION TODAY

Need to speak with someone in person about your custom dtg printing needs? Stop in at our office during business hours. We'd love to see you!

HOURS: (Mon - Fri) 8 am - 5 pm

PHONE: (986)777-9466

EMAIL: info@theprintplug.com

UNLIMITED COLORS!

DON'T BE LIMITED ON THE NUMBER OF GRADIENTS YOU CAN INCORPORATE INTO YOUR DESIGN.

Vector graphics work best, but we can work around the quality of your design and alter it to fit the order (fees may apply). The reason vector graphics are most commonly used is because they can be infinitely resized without losing any resolution or color quality, which is ideal for projects that need high quality images. DTG printing is a digital process; all we need is a high resolution art file that we can send to the printer and we will be able to print the shirt. Common file types for vector graphics include .ai (illustrator), .eps (encapsulated postscript), and .svg (scalable vector graphics). A high resolution PNG (portable network graphics) with a transparent background is preferred, and we can work with the art you give us (fees apply for reworking).

- .Ai (Adobe Illustrator)

- .eps (Encapsulated Postscript)

- .svg (Scalable Vector Graphic)

- .png (High Resolution Portable Network Graphic)

Or use our online quote request form.

SUBSCRIBE AND SAVE!

Sign up for our newsletter to receive exclusive access to discounts and savings. We send out 1 - 2 newsletters per month; we never share your information with anyone outside our organization. It is free to sign up and you can cancel anytime. So what are you waiting for?? We'll see you in there!

We proudly offer Direct-To-Garment, Embroidery, Vinyl, Sublimation, Screen Printing and more to greater Southwest Idaho and Eastern Oregon, including the following counties and cities:

Counties: Valley County - Adams County - Washington County - Payette County - Gem County - Canyon County - Boise County - Ada County - Elmore County - Camas County - Gooding County - Twin Falls County - Owyee County - Malheur County

Cities: McCall, Idaho - Council, Idaho - Indian Valley, Idaho - Midvale, Idaho - Cascade, Idaho - Smiths Ferry, Idaho - Ola, Idaho - Crouch, Idaho - Lowman, Idaho - Placerville, Idaho - Idaho City, Idaho - Stanley, Idaho - Atlanta, Idaho - Pine, Idaho - Mountain Home, Idaho - Glenns Ferry, Idaho - Grand View, Idaho - Oreana, Idaho - Murphy, Idaho - Boise, Idaho - Eagle, Idaho - Meridian, Idaho - Garden City, Idaho - Nampa, Idaho - Caldwell, Idaho - Emmett, Idaho - Payette, Idaho - Weiser, Idaho - Grasmere, Idaho - Riddle, Idaho - Castleford, Idaho - Buhl, Idaho - Hollister, Idaho - Twin Falls, Idaho - Ragerson, Idaho - Jerome, Idaho - Hagerman, Idaho - Gooding, Idaho - Fairfield, Idaho - Ontario, Oregon

NOT LOCAL? NO PROBLEM! TALK TO US ABOUT FAST AND FREE SHIPPING ON ORDERS OVER $200