DIRECT-TO-FILM / DTF PRINTING SERVICES IN NAMPA

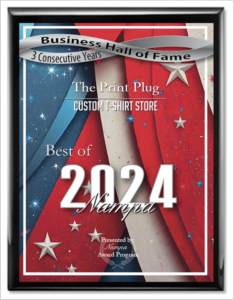

WINNER OF BEST CUSTOM T-SHIRT SHOP FOR 3 YEARS

We are so proud and excited to be recipients of Nampa's Best Custom T-Shirt Shop Award for three years and running! We are grateful to all of our customers who have supported us in this journey, and look forward to serving you in your custom clothes and apparel printing and embroidery needs for many more years to come. Read the full press release here!

WHY CHOOSE CUSTOM DTF PRINTING?

We at The Print Plug are very proud of our stellar 5-Star rating on Google. We believe it serves as evidence of our unwavering commitment to customer satisfaction. Whether it's screen printing on a shirt, custom embroidery on a jacket, or next-day direct-to-garment printing, you can rest assured knowing that you job is in good hands!

When time is of the essence; we've got your back! The Print Plug offers a 24 hour turnaround on most DTF custom clothes orders, and a two-week turnaround on most custom garment screen print and embroidery orders.

Need a next-day custom t-shirt? No problem! 24 hour custom DTF tees are what we do best! With full-color prints, no minimum orders, and our money-back guarantee, you can rest easy knowing that you won't be sacrificing quality.

In a serious time crunch? Ask about our expedited turnarounds!

Vector graphics work best, but we can work around the quality of your design and alter it to fit the order (fees may apply). The reason vector graphics are most commonly used is because they can be infinitely resized without losing any resolution or color quality, which is ideal for projects that need high quality images. DTF printing is a digital process; all we need is a high resolution art file that we can send to the printer and we will be able to print the shirt. Common file types for vector graphics include .ai (illustrator), .eps (encapsulated postscript), and .svg (scalable vector graphics). A high resolution PNG (portable network graphics) with a transparent background is preferred, and we can work with the art you give us (fees apply for reworking).

- .Ai (Adobe Illustrator)

- .eps (Encapsulated Postscript)

- .svg (Scalable Vector Graphic)

- .png (High Resolution Portable Network Graphic)

SUBSCRIBE AND SAVE!

Sign up for our newsletter to receive exclusive access to discounts and savings. We send out 1 - 2 newsletters per month; we never share your information with anyone outside our organization. It is free to sign up and you can cancel anytime. So what are you waiting for?? We'll see you in there!

Discover the future of custom clothes printing with The Print Plug's cutting-edge Direct-to-Film t-shirt printing service in Nampa, Idaho.

Our DTF printing technology offers a multitude of benefits, including the ability to bring your designs to life in vibrant full-color, and it's not limited to traditional fabrics; we can print onto synthetic materials like polyester, opening up a world of possibilities for your creative projects and custom clothes printing needs.

Best of all, there are no minimum order requirements, making our DTF service accessible to individuals and businesses alike.

At The Print Plug, we understand the value of speed and quality. That's why we proudly offer next-day turnaround on most DTF printing orders, ensuring that you get your custom prints exactly when you need them.

With a stellar 5-star Google rating, we've earned our reputation for delivering exceptional results. If you're ready to explore the versatility and vividness of direct-to-film printing in Idaho, don't hesitate to contact us at 986-777-9466.

Let's collaborate to turn your creative ideas into reality, right here in Nampa.

Or use our online quote request form.

We proudly offer Direct-To-Garment, Embroidery, Vinyl, Sublimation, Screen Printing and more to greater Southwest Idaho and Eastern Oregon, including the following counties and cities:

Counties: Valley County - Adams County - Washington County - Payette County - Gem County - Canyon County - Boise County - Ada County - Elmore County - Camas County - Gooding County - Twin Falls County - Owyee County - Malheur County

Cities: McCall, Idaho - Council, Idaho - Indian Valley, Idaho - Midvale, Idaho - Cascade, Idaho - Smiths Ferry, Idaho - Ola, Idaho - Crouch, Idaho - Lowman, Idaho - Placerville, Idaho - Idaho City, Idaho - Stanley, Idaho - Atlanta, Idaho - Pine, Idaho - Mountain Home, Idaho - Glenns Ferry, Idaho - Grand View, Idaho - Oreana, Idaho - Murphy, Idaho - Boise, Idaho - Eagle, Idaho - Meridian, Idaho - Garden City, Idaho - Nampa, Idaho - Caldwell, Idaho - Emmett, Idaho - Payette, Idaho - Weiser, Idaho - Grasmere, Idaho - Riddle, Idaho - Castleford, Idaho - Buhl, Idaho - Hollister, Idaho - Twin Falls, Idaho - Ragerson, Idaho - Jerome, Idaho - Hagerman, Idaho - Gooding, Idaho - Fairfield, Idaho - Ontario, Oregon

NOT LOCAL? NO PROBLEM! TALK TO US ABOUT FAST AND FREE SHIPPING ON ORDERS OVER $200