Custom Screen Printing 101: A Brief Overview of a Powerful Medium

Screen printing is a popular technique used to print designs on t-shirts, as well as other types of fabric.

This process involves creating a stencil, also known as a screen, which is then used to transfer ink onto the fabric. This method is an excellent way to create high-quality, long-lasting designs that can withstand regular use and washing.

The Screen Printing Process

If you’re considering screen printing on t-shirts, here are some key things to keep in mind:

- Design Creation: The first step in screen printing is to create a design. This can be done using software like Adobe Illustrator or by hand with pen and paper. Once the design is complete, it needs to be converted into a stencil that can be used for printing. This is typically done by a professional screen printer, but if you have experience with screen printing, you can do it yourself using a special type of film or paper.

- Color Selection: Silk screening allows for a wide range of colors, but each color requires a separate stencil and printing process. If you’re working with a limited budget or time, you may want to limit your design to just one or two colors. Keep in mind that some colors, such as white, can be printed on any color fabric, while other colors may require a specific base color to be used.

- Fabric Selection: Screen printing can be done on a variety of fabrics, but cotton is the most commonly used material for t-shirts. It’s important to choose a fabric that will hold up well to regular wear and washing, as well as one that will show the colors of your design clearly.

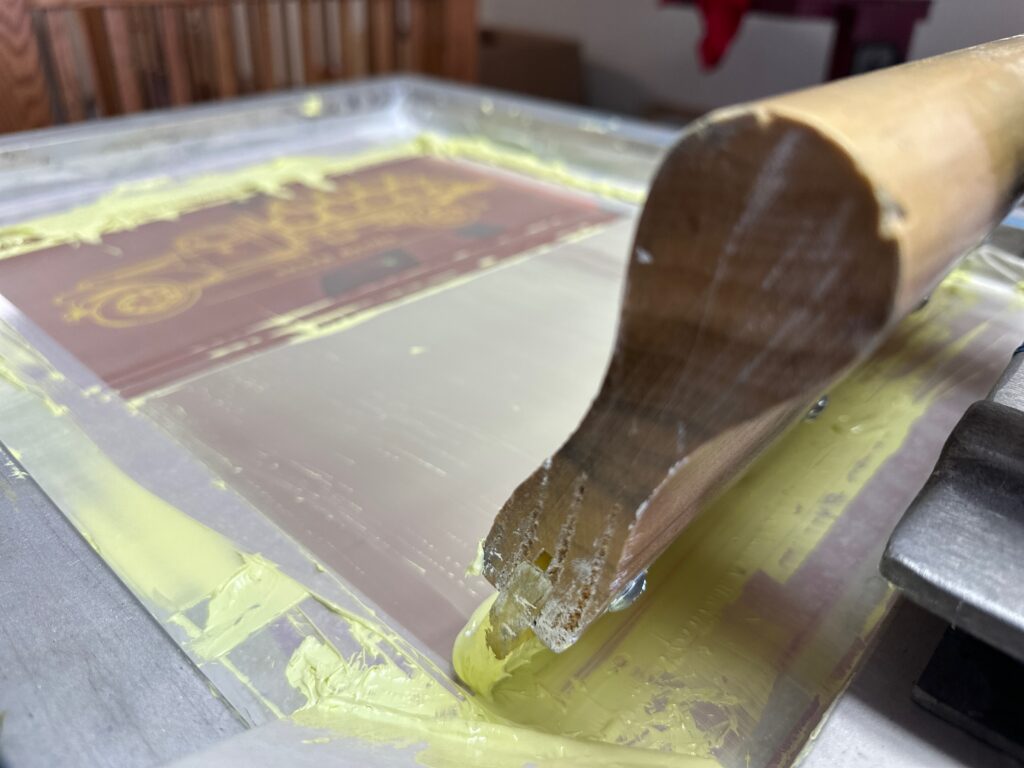

- Printing Process: Once your stencils are created, the printing process can begin. The fabric is stretched over a flat surface, and the stencil is placed on top. Ink is then poured onto the stencil and pushed through with a squeegee, transferring the design onto the fabric. This process is repeated for each color in your design, with the ink being allowed to dry between each layer.

- Finishing Touches: Once the printing is complete, the t-shirts are typically cured in a heat press or oven to ensure the ink sets properly. This can also help to prevent the design from cracking or fading over time. After curing, the t-shirts can be folded and packaged for shipping or distribution.

Screen Printing: A Custom Garment Solution

Screen printing is a great option for creating high-quality, custom t-shirts with a unique design. Whether you’re creating t-shirts for your business, event, or personal use, the screen printing process can help you achieve a professional-looking product that will last for years to come.

Call The Print Plug today to discuss your next custom garment project and to see if screen printing is the right solution for you.