DTG Printing / Direct-to-Garment: A Powerful New Medium

Direct-to-garment, or DTG printing, is a relatively new technology that allows for full-color, high-quality printing on a variety of fabrics. This process involves using a specialized printer to apply ink directly to the fabric, rather than using a stencil or transfer sheet as in other printing techniques.

DTG Printing Explained

Here are some key things to keep in mind if you’re considering DTG printing for your next project:

1. Design Creation:

As with other printing techniques, the first step in DTG printing is to create a design. This can be done using software like Adobe Illustrator or by hand with pen and paper. Once the design is complete, it needs to be converted into a digital file that can be read by the DTG printer.

2. Fabric Selection

Direct-to-Garment printing can be done on a variety of fabrics, including cotton, polyester, and blends. However, it’s important to choose a fabric that will hold up well to regular wear and washing, as well as one that will show the colors of your design clearly.

3. Pre-Treatment

For most DTG printing, especially dark garments, it is necessary to treat the garment with a solution that will help bind the ink to the fabric. This process is called pre-treating, and is a critical step in ensuring that your final image is vibrant and durable.

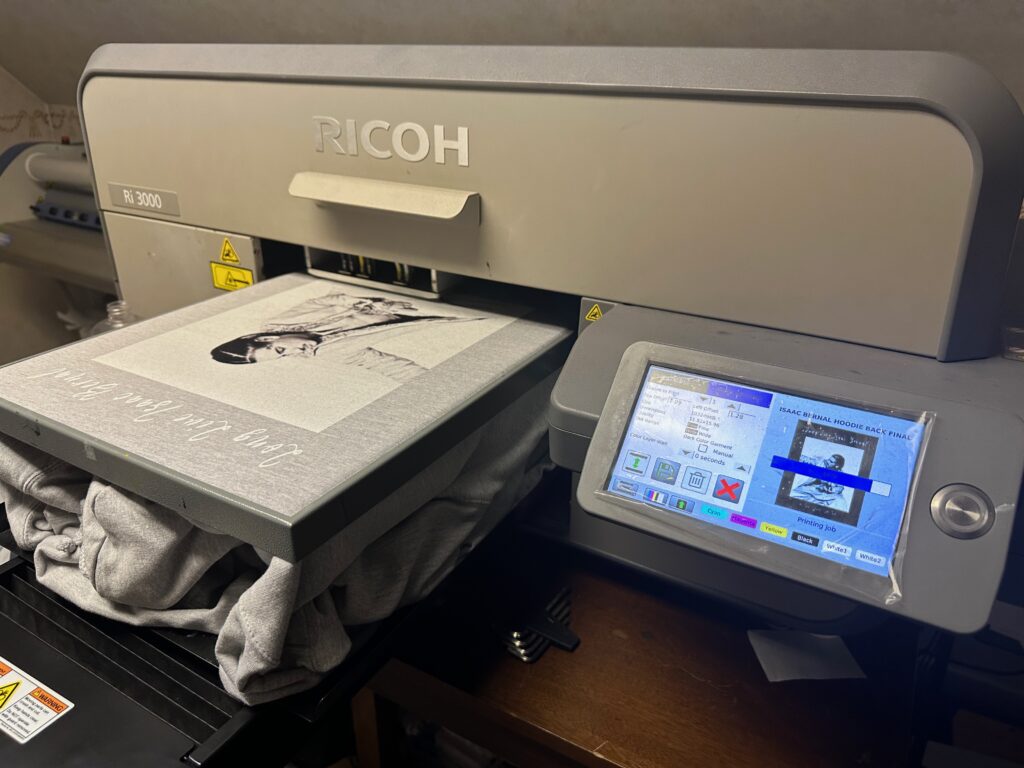

4. Printing Process

Once your digital file is ready and the fabric has been pre-treated, the printing process can begin. The fabric is placed onto a flat surface, and the printer applies ink directly to the fabric using a series of nozzles. The ink is absorbed into the fabric, creating a high-quality, full-color design that’s soft to the touch.

5. Curing

After printing, the fabric is typically cured in a heat press or oven to ensure the ink sets properly. This can also help to prevent the design from cracking or fading over time.

6. Finishing Touches

Once the fabric is cured, the finished product may undergo additional finishing touches to ensure the design looks its best. This can include trimming any excess threads, ironing the fabric to remove any wrinkles, and packaging the item for shipping or distribution.

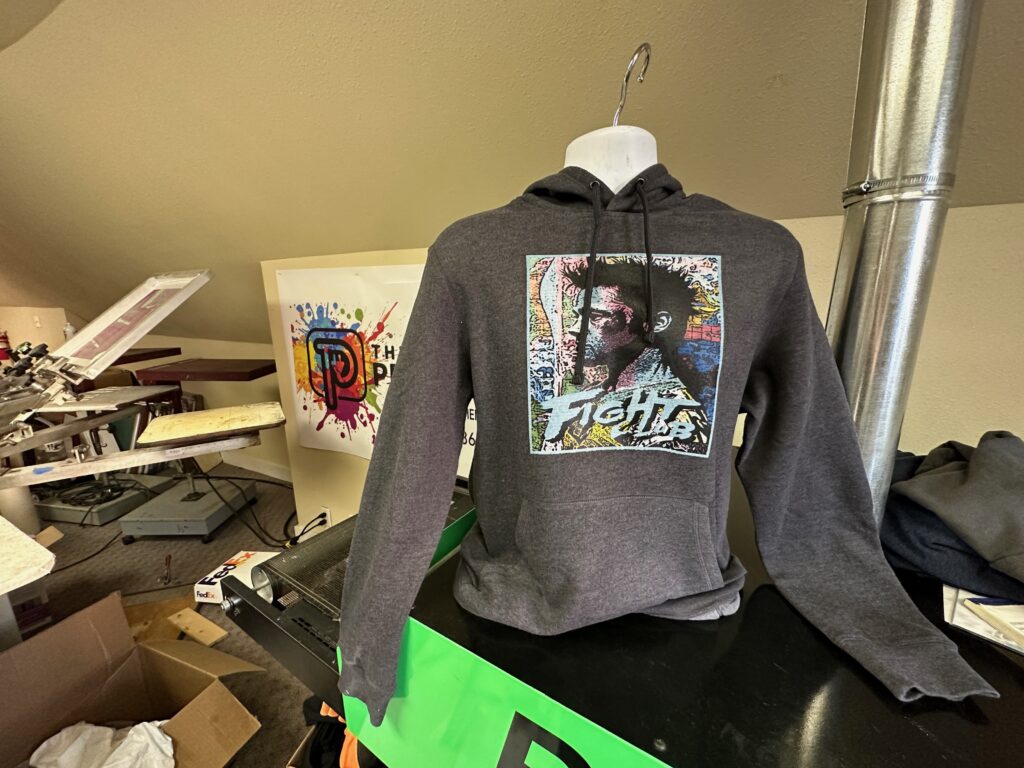

DTG printing is a great option for creating high-quality, custom designs with vibrant colors and a soft, comfortable feel. Whether you’re creating t-shirts for your business, event, or personal use, the DTG printing process can help you achieve a professional-looking product that will last for years to come.

Additionally, since there are no setup costs or minimum order requirements, Direct-to-Garment printing is a cost-effective option for printing small quantities or one-of-a-kind items.

The Print Plug is home to some serious Direct-to-Garment enthusiasts. We also specialize in screen printing, embroidery, heat-transfer-vinyl and more. Check out our Google page, full of positive reviews from our satisfied customers. You can also check out our gallery to see some of the jobs that have come through our doors. Then give us a call today to go over your project and decide if DTG printing is right for you.