DTF vs DTG: Comparing Direct-to-Film and Direct-to-Garment Printing

For more information, call The Print Plug of Idaho at 986-777-9466

DTF, direct-to-film printing, and DTG, direct-to-garment printing, are two popular methods for customizing garments with unique features and benefits. Understanding the differences and advantages of each technique can help you make an informed decision on which one best suits your designs and brand. Whether you’re starting a t-shirt business or simply interested in learning more about printing techniques, let’s dive into a comprehensive comparison of DTF and DTG printing.

DTF vs DTG: Everything You Need to Know

What is DTF printing?

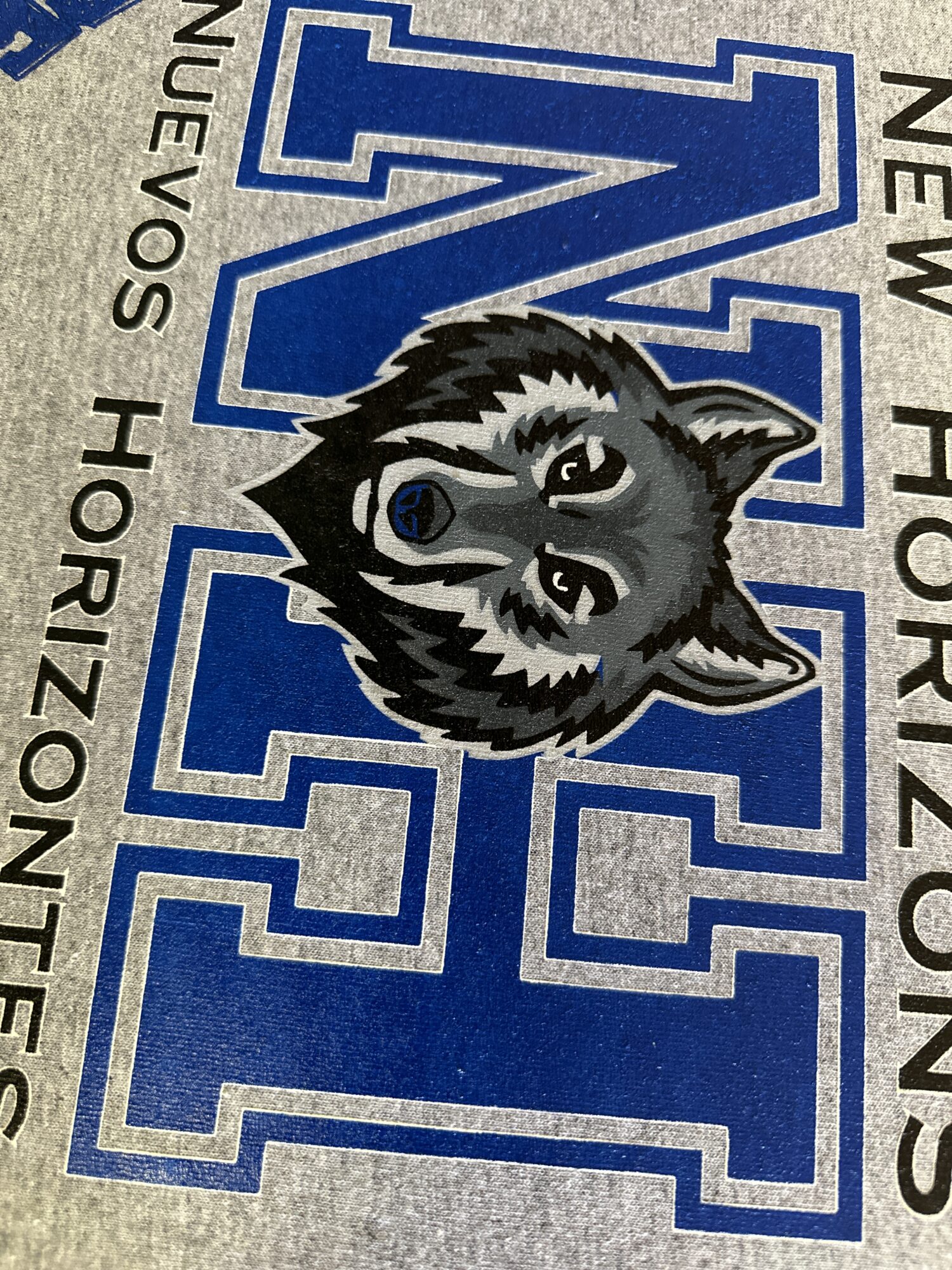

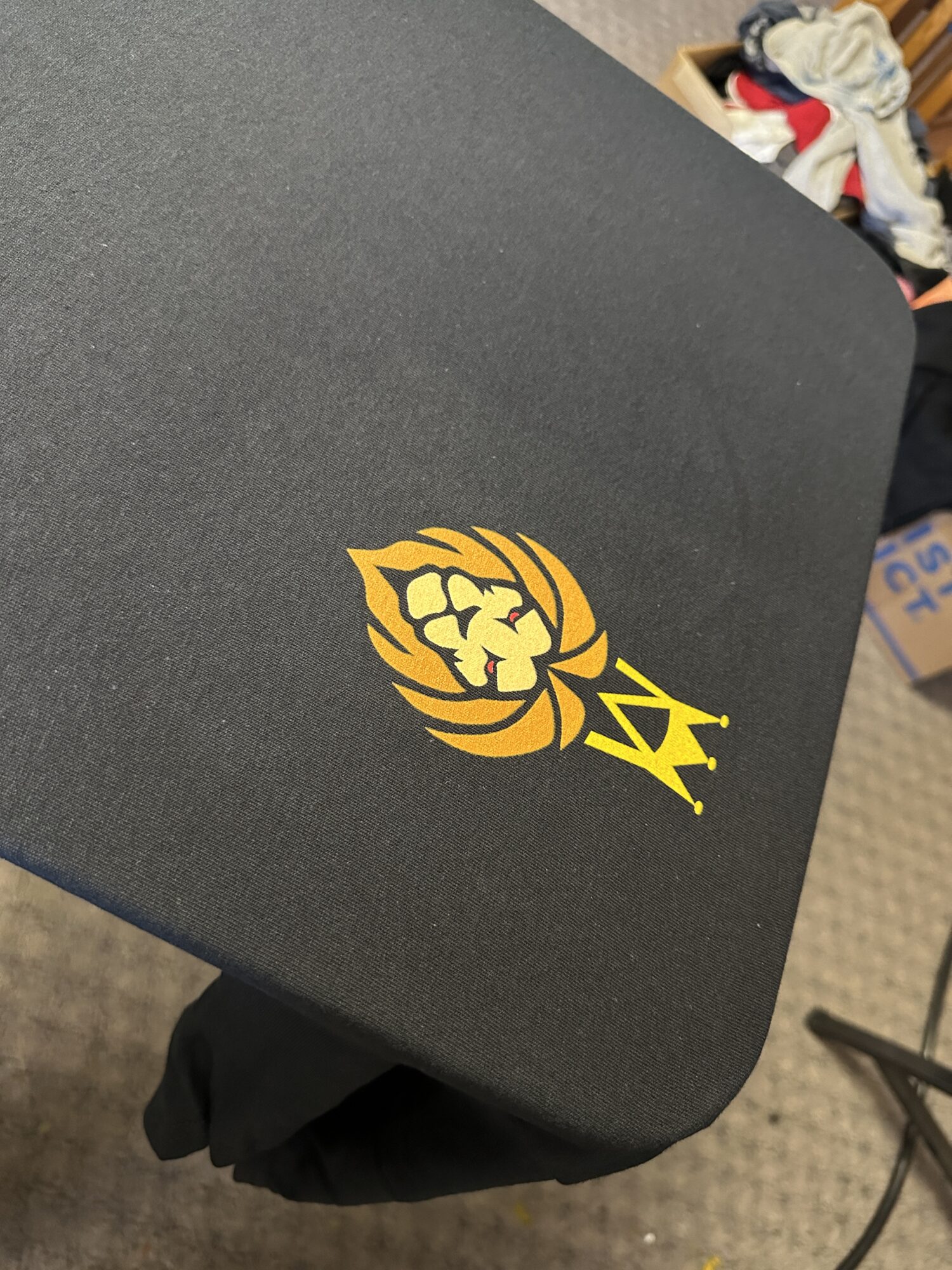

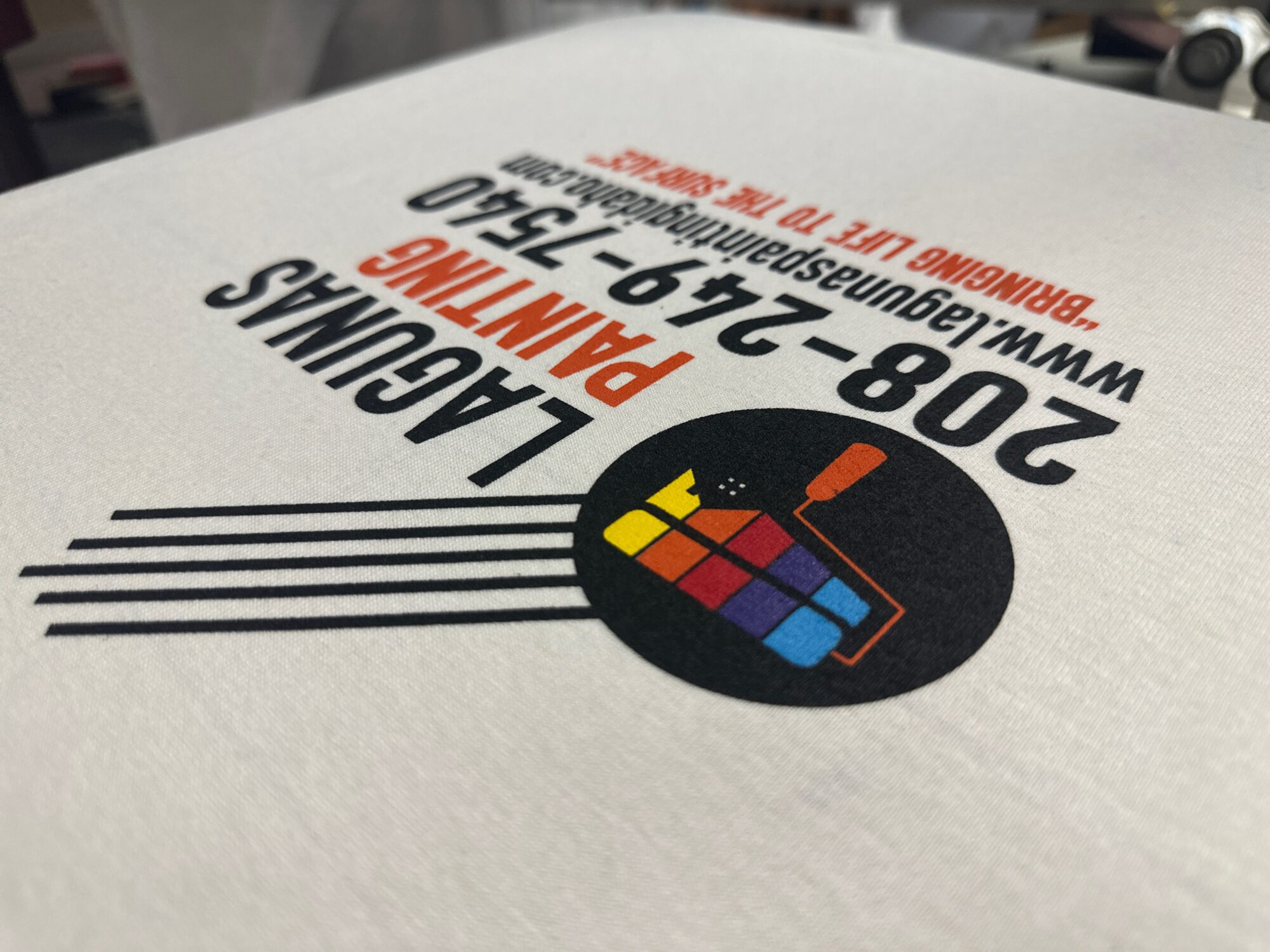

DTF printing is a relatively new technique that has gained popularity for its excellent color accuracy, detail, and durability. It offers a wide range of color options and is capable of printing on both dark and light garments. DTF is suitable for various material types, including polyester, cotton, nylon, and fleece, making it a versatile choice for customizing apparel.

How does DTF printing work?

The DTF printing process involves several steps:

Design Printing: The design is printed onto a special transfer film using water-based inks.

Adhesive Coating: The ink on the film is coated with a special adhesive powder.

Heat Transfer: The design is then transferred onto the fabric using a heat press.

Despite the multiple steps involved, the print time for one garment is relatively short, making DTF an efficient method for on-demand production.

What is DTG printing?

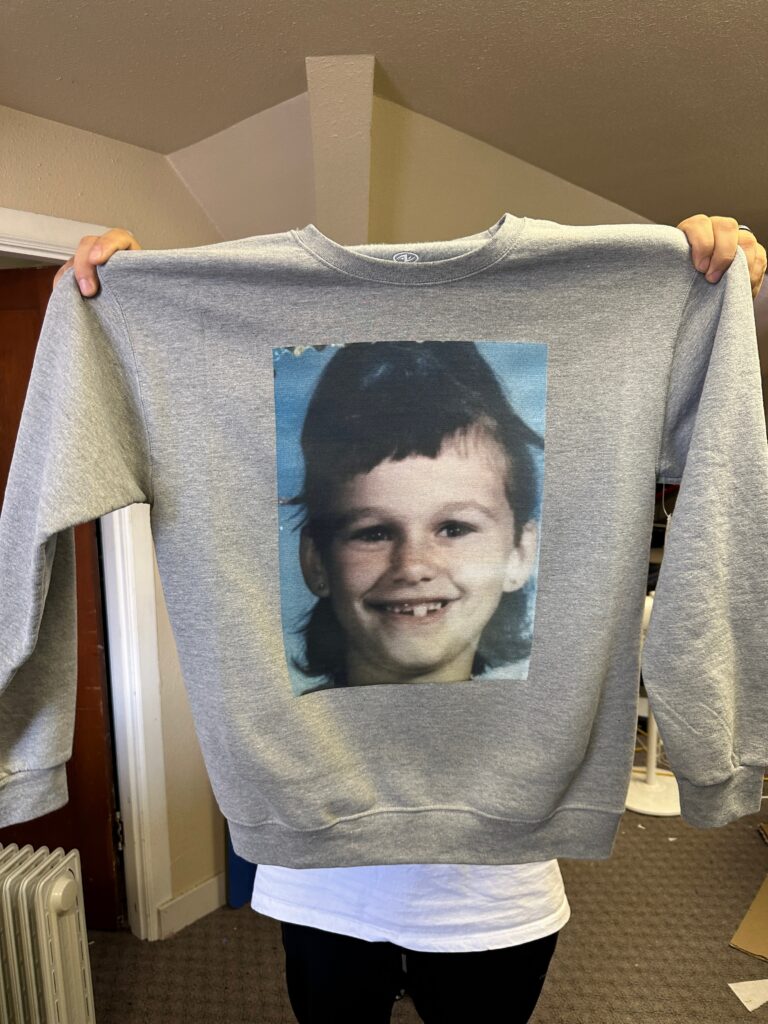

DTG printing, on the other hand, involves spraying ink directly onto the garment to create high-quality, full-color prints. The technique is best suited for natural fabrics like cotton, bamboo, and linen, as the material absorbs the ink effectively. DTG is a popular choice for on-demand production, allowing for easy printing of one-offs without extensive setup time.

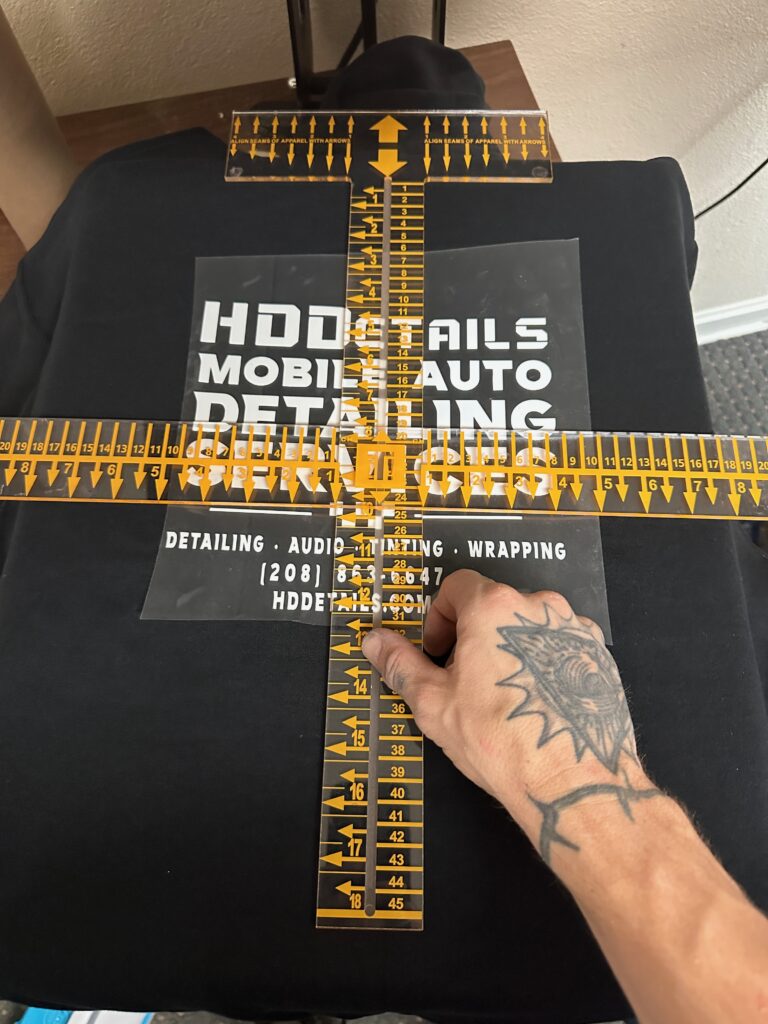

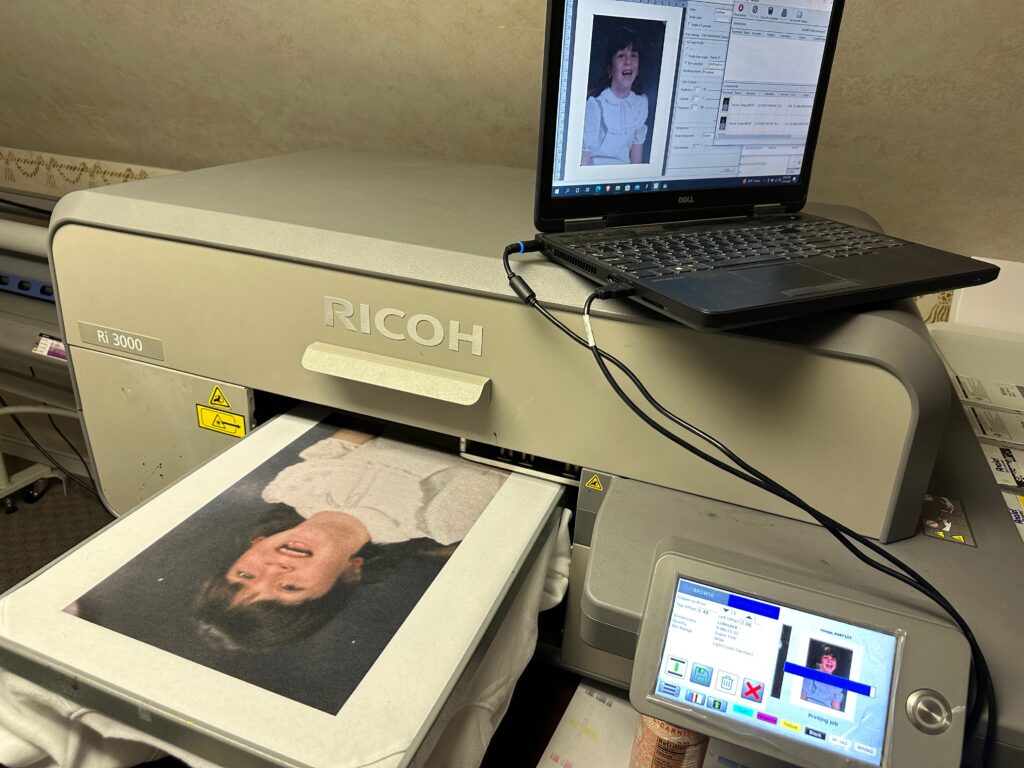

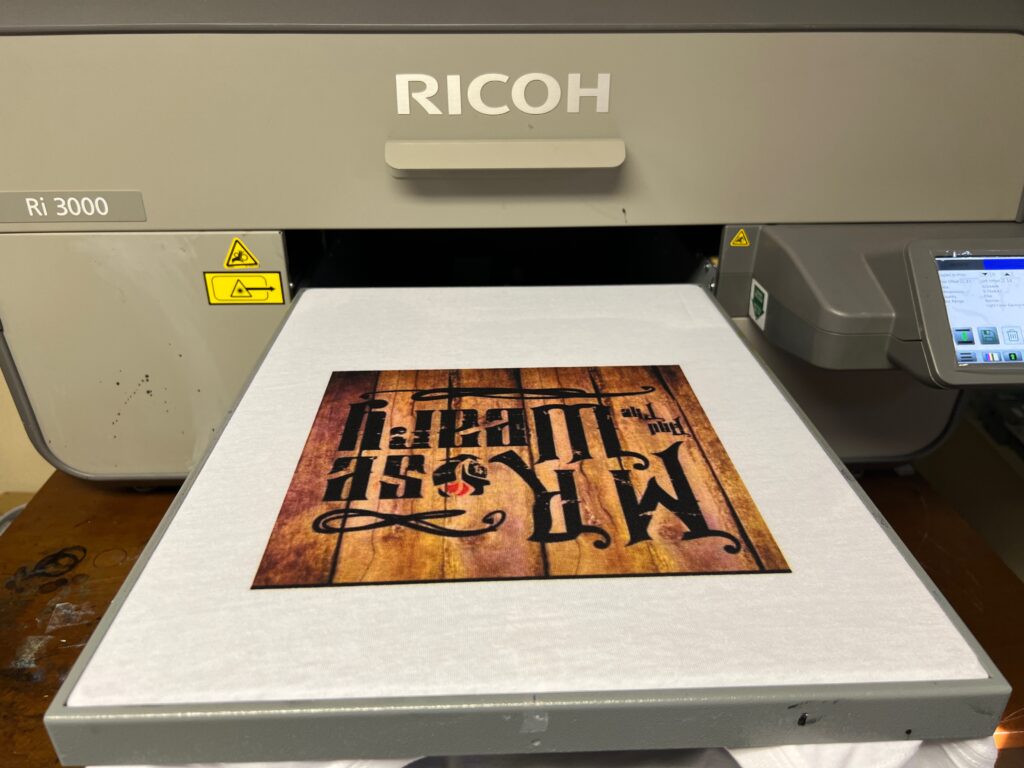

How does DTG printing work?

The DTG printing process is simpler and involves the following steps:

Pre-Treatment: The garment is treated with a pre-treatment solution to help the ink bond with the fabric.

Printing: The garment is mounted on a platen, and the design is sprayed onto the fabric using water-based inks.

Ink Curing: The ink is cured to increase its durability and longevity.

DTG prints are soft, breathable, and durable, making them ideal for various apparel items.

DTF vs DTG Printing: What Are the Differences?

While both DTF and DTG printing produce impressive results, there are notable differences between the two techniques.

Print quality and durability:

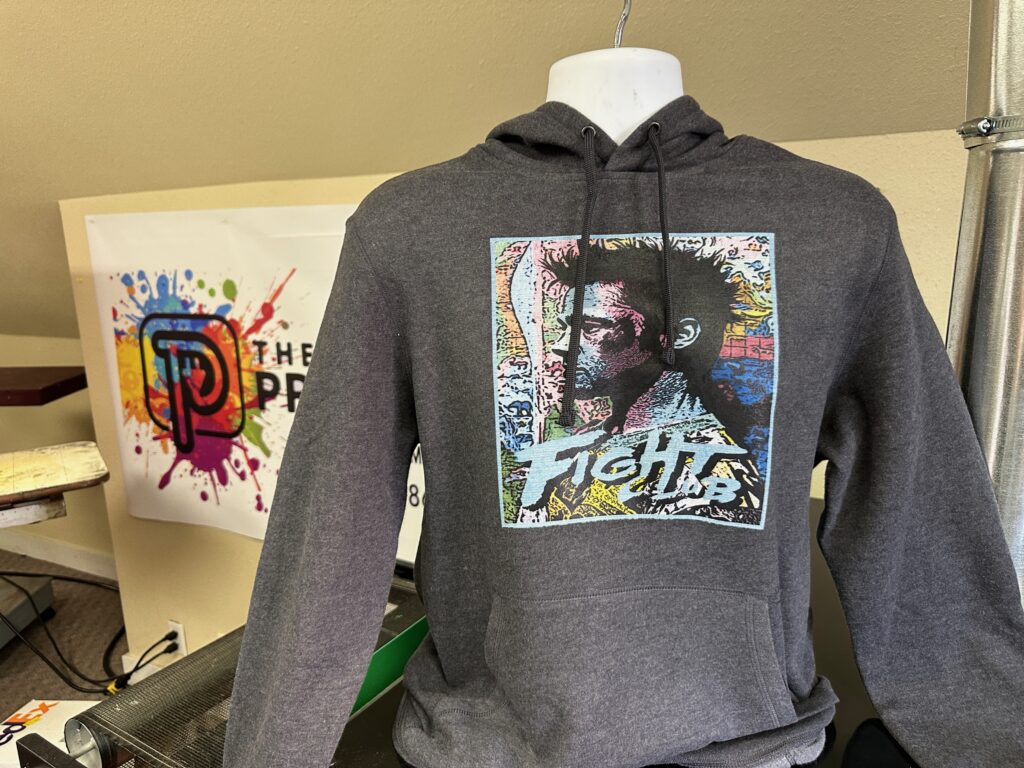

DTF prints offer excellent quality with smooth and elastic results. They are resistant to cracking and can withstand heavy use and washes without fading color. However, they may develop small cracks if washed in very hot water. DTF is particularly suitable for printing photos, colorful designs, graphics, and fine art, as the ink sits on top of the fabric, resulting in thin and non-bulky prints.

DTG prints also provide fantastic quality with vibrant, clear, and detailed results. The prints may initially feel slightly rough but smoothen after a few washes. While the fabric absorbs the ink in DTG printing, the prints are still durable, long-lasting, and won’t crack, peel, or fade when proper care instructions are followed.

Print complexity:

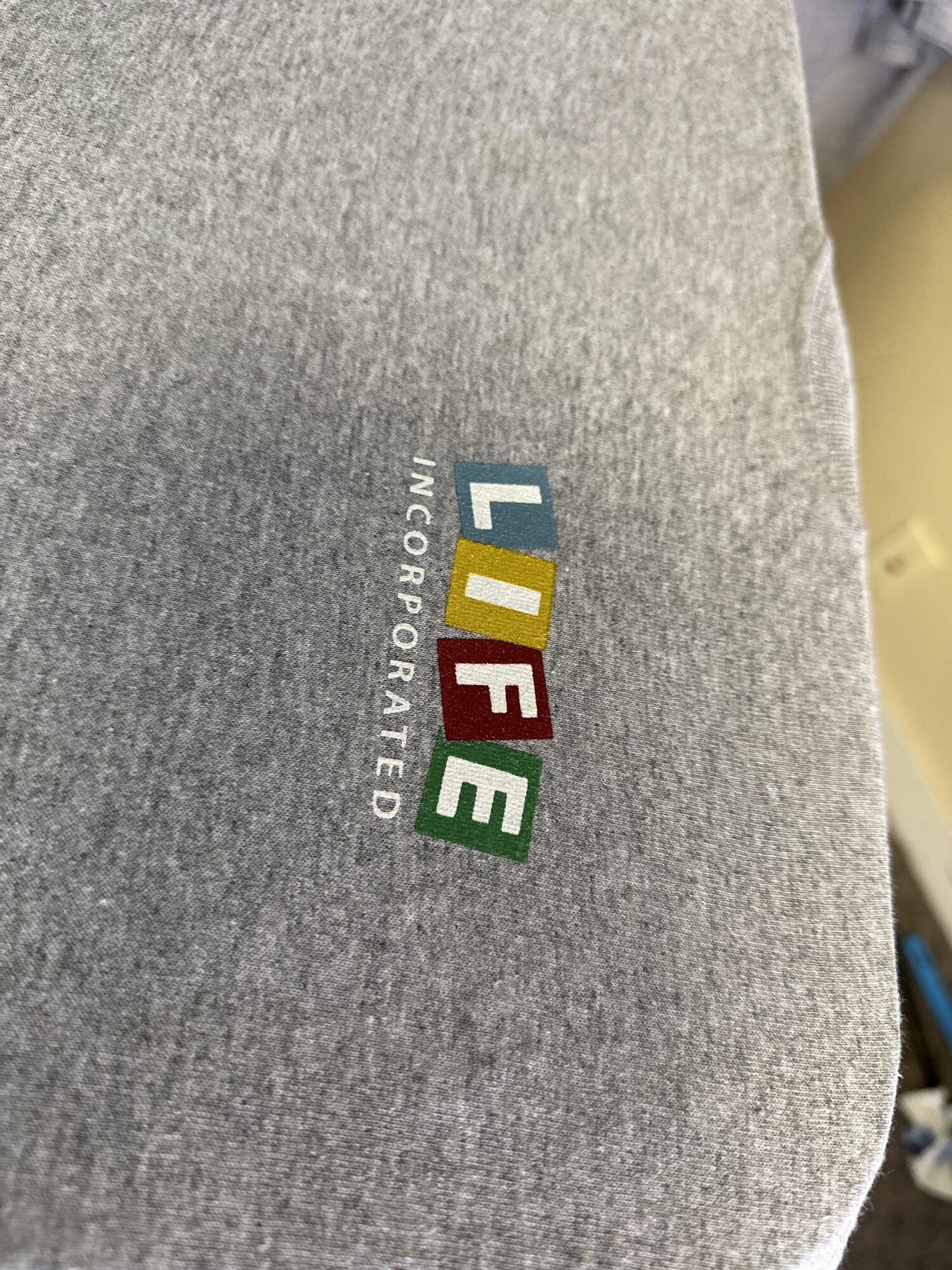

DTF printing excels in print complexity, supporting photos, detailed designs, full-color artwork, small text, graphics, and gradients. The prints are sharp, clear, and realistic, making them an excellent choice for intricate designs.

DTG printing also supports colorful designs, graphics, photos, and more. However, it may not achieve the same level of clarity as DTF prints due to the fabric’s ink absorption. Printing gradients with DTG can be challenging, and adjustments may be necessary to achieve the desired outcome.

Color vibrancy:

DTF printing uses primary colors (CMYK) and white ink for the base, resulting in vibrant and vivid prints on all fabric colors and types.

DTG printing also uses the CMYK color model but includes a white base color only when printing on black or colorful garments. When printing on white fabrics, the white base color is not used. The fabric’s ink absorption may result in slightly less bright or vivid prints compared to DTF printing.

Fabric suitability:

DTF printing offers the advantage of printing on various fabrics, including polyester, cotton, fleece, nylon, and fabric blends. The material type does not significantly impact the print quality.

In contrast, DTG is best suited for natural fabrics like cotton, bamboo, linen, and fabric blends. The ink bonds better with natural fibers, ensuring high-quality prints.

Quantity:

DTF printing is an excellent choice for on-demand production, allowing printing of one shirt or bulk orders with ease.

Similarly, DTG technology is ideal for small and large orders alike. This printing method is widely used in dropshipping companies due to its flexibility in accommodating various order quantities.

Eco-friendliness:

Both DTF and DTG printing offer eco-friendly fulfillment methods. DTF printing allows for on-demand production, reducing the risk of unsold stock and eliminating overproduction. The water-based and non-toxic inks used in DTF printing contribute to its environmental friendliness. Additionally, the recyclable transfer film minimizes waste during the printing process.

DTG printing also supports on-demand production, ensuring that only the exact amount of products ordered are printed, reducing overproduction. DTG machines from companies like Kornit produce almost zero wastewater and use less energy, lowering the carbon footprint. The water-based vegan inks used in DTG are non-hazardous, toxin-free, biodegradable, and contain no animal by-products.

On-demand fulfillment:

Both DTF and DTG printing techniques support on-demand fulfillment, making it possible to order single items or multiple items without affecting the production cost.

Upfront investment:

Working with a print-on-demand company like The Print Plug eliminates the need for an upfront investment in DTF or DTG printing equipment. With print-on-demand, products are made only when a customer places an order, and the profit is retained after paying for the item’s production.

However, if you choose to print garments yourself, you’ll need to invest in a DTF or DTG printer, blank products, DTF or DTG inks, and other materials for fulfilling and shipping orders. The decision to invest in equipment will depend on your business scale and whether dropshipping products align with your brand strategy.

DTF printing and DTG: what designs each printing process is better for?

After exploring the features of each printing method, it’s evident that both DTF and DTG printing deliver exceptional results, catering to different design needs.

When to choose direct-to-film printing:

DTF technology is ideal if your business focuses on selling items made with polyester, nylon, fleece, or other synthetic materials. It also opens up the possibility of printing on various other products like bags and hats, expanding your product range.

For detailed and colorful designs requiring the best print quality, DTF printing is an excellent choice. DTF prints produce vivid and sharp results that are long-lasting and durable.

However, if your design features a large print, such as a photo, DTF printing may not be the most comfortable option due to its lack of breathability on large designs. Consider testing your designs on different printing techniques before selling items with DTF prints.

When to choose direct-to-garment printing:

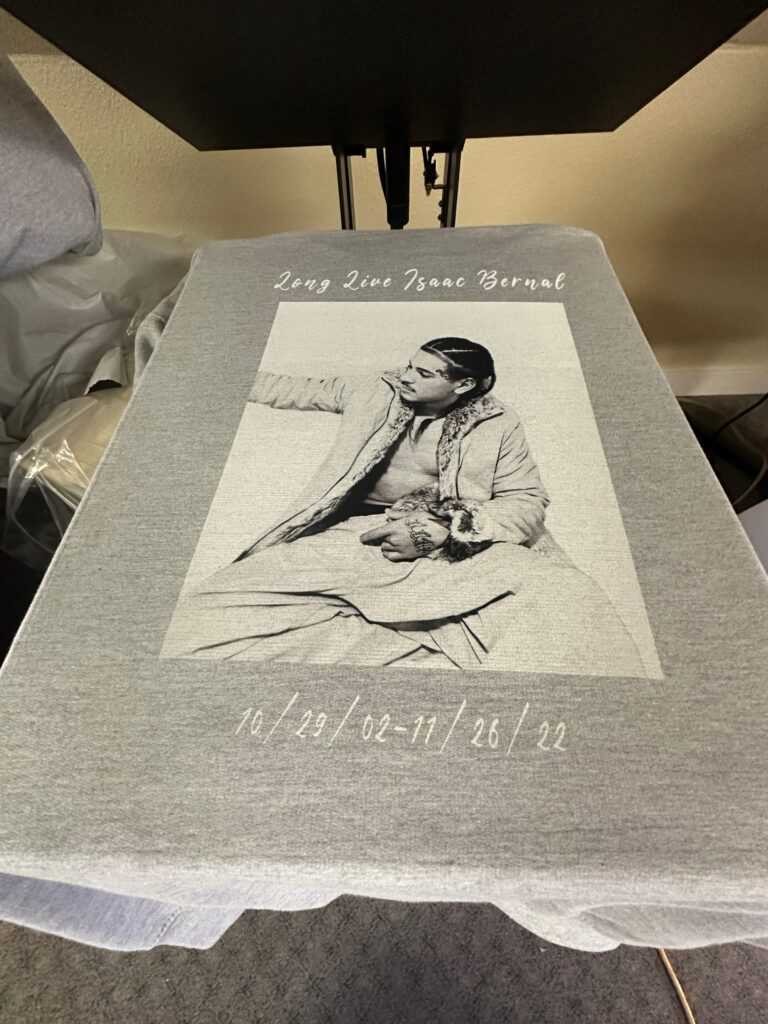

If your focus is on selling cotton garments or products made with other natural materials, DTG printing is the way to go. The versatility of DTG allows you to print on various apparel items, including tote bags, offering a wide range of product choices.

For less intricate designs, such as text, logos, or graphic art, DTG printing provides an excellent outcome. While DTG also supports colorful designs and images, keep in mind that prints may not be as clear or sharp as DTF prints.

Direct-to-garment prints are breathable, durable, and perfect for printing larger designs. It’s a popular printing method with reliable results that align with most design needs.

DTF vs DTG: Frequently Asked Questions (FAQs):

Do DTF prints last longer than DTG?

Both DTF and DTG prints are durable and long-lasting when proper care instructions are followed. The prints won’t crack, peel, or fade over time.

Is DTF printing worth it?

DTF printing is a worth-considering option, especially for businesses focusing on polyester, nylon, fleece, and synthetic material products. It provides excellent print quality, vibrant colors, and a wide range of product options.

How long does a DTF print last?

With proper care, DTF prints are long-lasting and resistant to cracking, fading, and heavy use. Wash garments in cold to lukewarm water to maintain print integrity.

Which is better—screen printing or DTF printing?

Both screen printing and DTF printing have their advantages and disadvantages. Screen printing is ideal for large quantities and simple designs, while DTF printing excels in print complexity, detailed designs, and photo prints.

Do DTF printing transfers crack?

DTF prints are resistant to cracking, but if garments are washed in very hot water, small cracks may develop.

DTF printing or DTG printing: which one will you choose?

In conclusion, both DTF and DTG printing methods offer fantastic results and are suitable for on-demand production. Each technique has its strengths and is better suited for certain design types or fabric materials.

DTF printing is an excellent choice for detailed and colorful designs on synthetic fabrics and offers unparalleled print complexity. DTG printing, on the other hand, is perfect for less intricate designs on natural fabrics and provides soft, breathable prints that are great for larger designs.

Ultimately, the decision comes down to your specific business needs and design preferences. Don’t be afraid to experiment with both techniques on different products to find the one that best complements your designs and aligns with your brand strategy.

Feel free to call he Print Plug with any questions you may have about DTG and DTF printing. We are a leader in the custom apparel and merchandise industry and are happy to help however we can!

Check out our Official Website

Check out our New Design Studio